Cushing Oklahoma Oil Storage Operators: Are You Making These Common Compliance Mistakes?

- pdoyle57

- Nov 24, 2025

- 5 min read

Your storage facility could be one inspection away from a catastrophic shutdown. Every day, Cushing Oklahoma oil storage operators roll the dice with compliance violations that could cost them millions in fines, force operational shutdowns, and destroy years of built reputation. The worst part? Most of these violations are completely preventable.

As the pipeline crossroads of America, Cushing hosts some of the nation's most critical oil storage infrastructure. But with great importance comes intense regulatory scrutiny. You're operating under a microscope – and regulators know exactly where to look for violations.

Are you confident your facility would pass an unannounced inspection today?

The SPCC Plan Trap That Catches Everyone

Here's the reality check most operators don't want to hear: Your Spill Prevention, Control, and Countermeasure (SPCC) plan is probably outdated, incomplete, or both. The EPA doesn't care that you've been too busy to update it – they care that you're out of compliance.

The Update Nightmare

Every facility expansion, equipment upgrade, or operational modification requires plan updates. Think you can slide by with that new tank installation from six months ago? Think again. The EPA specifically requires SPCC plan reviews every five years or after significant changes, yet facility after facility gets nailed for this seemingly simple requirement.

Your SPCC plan isn't a "set it and forget it" document – it's a living, breathing compliance tool that must evolve with your operations.

Secondary Containment Disasters

Picture this scenario: Your inspector arrives to find your secondary containment system compromised, corroded, or completely inadequate. Game over. Secondary containment violations represent some of the most expensive compliance failures because they directly threaten environmental protection.

Many operators construct containment that looks adequate on paper but fails in practice. Your containment must actually contain – not just check a regulatory box. Cracked concrete, insufficient capacity, and poor drainage design are compliance killers that can shut you down faster than you can say "environmental violation."

The Monthly Inspection Trap

Monthly inspections aren't suggestions – they're federal requirements. Yet facility after facility fails to conduct proper monthly inspections of oil storage equipment. Missing documentation, incomplete checklists, and "we forgot" excuses don't fly with regulators who can access years of inspection records instantly.

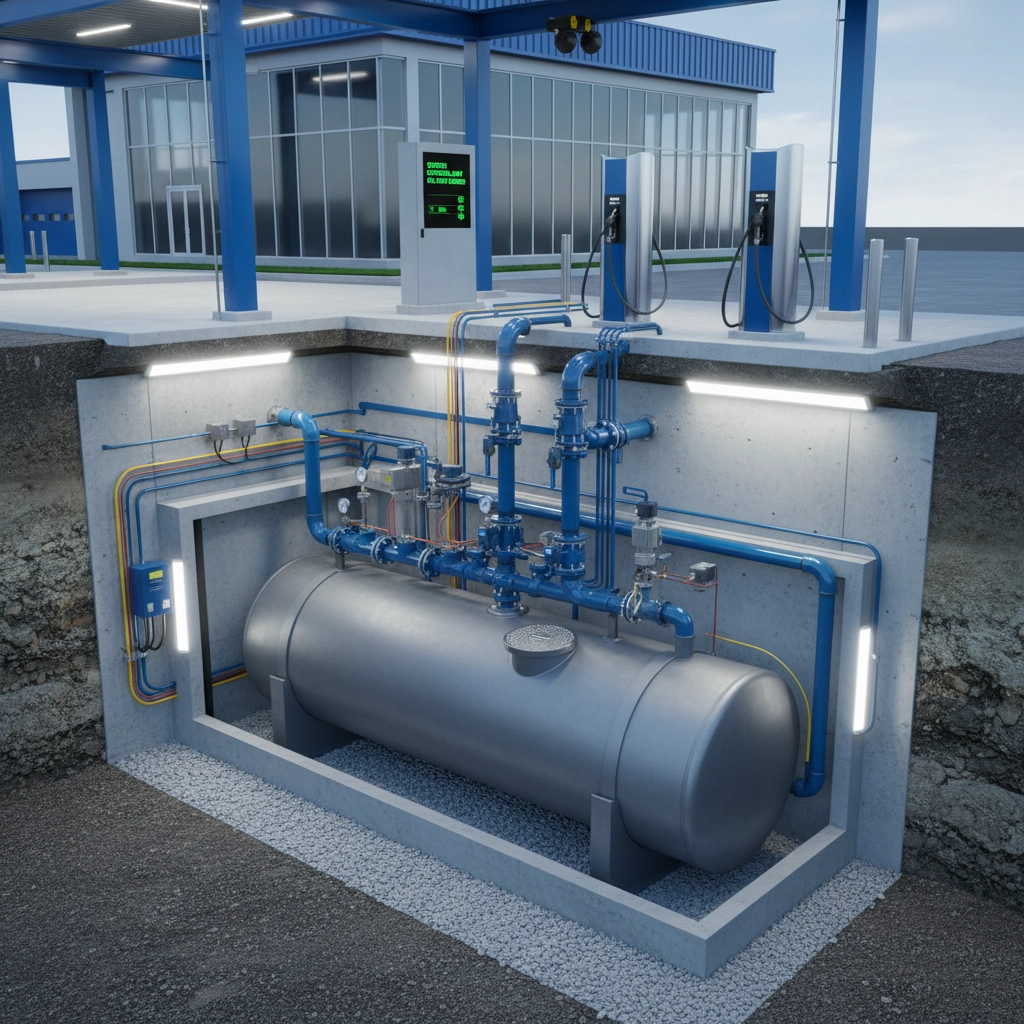

Underground Storage Tank Compliance Nightmares

If you operate underground storage tanks (USTs) in your Cushing Oklahoma oil storage facility, you're navigating an especially treacherous compliance landscape. UST violations can trigger immediate operational restrictions and massive financial penalties that devastate smaller operators.

Secondary Containment: The #1 Violation

Secondary containment deficiencies represent the leading individual violation at facilities inspected since compliance programs began. Your spill prevention capacity during fuel delivery must meet exact specifications – and "close enough" isn't good enough for federal inspectors.

Are your containment systems properly sized? Regularly tested? Adequately maintained? One containment failure can trigger a cascade of violations that multiply your penalties exponentially.

Operator Training Documentation Disasters

Every operator must maintain readily available training records. Sounds simple, right? Wrong. Facilities consistently fail to provide copies of operator training documents during inspections. Your training certificates must be on-site, current, and complete – no exceptions.

Remember: Your best-trained operator means nothing to regulators if you can't prove they received proper certification. Documentation failures can invalidate years of operational compliance and trigger immediate training requirements for your entire team.

Financial Responsibility Requirements

Can you prove you have adequate financial responsibility for corrective action costs? Facility owners and operators must demonstrate financial capacity for petroleum release cleanup and third-party compensation. This isn't optional – it's a federal mandate that catches unprepared operators off-guard during inspections.

Missing financial responsibility documentation or inadequate coverage levels create immediate compliance violations that can restrict your operational authority while you scramble to secure proper coverage.

NSPS OOOO Oversights That Cost Millions

New Source Performance Standards (NSPS OOOO) compliance represents one of the most complex regulatory challenges facing modern oil storage operators. The methane emission standards and leak detection requirements create ongoing compliance obligations that many Cushing operators underestimate.

Your facility's NSPS OOOO compliance affects everything from equipment selection to maintenance scheduling to reporting requirements. One missed emission detection requirement can trigger violations that multiply across your entire operation.

Are your leak detection programs adequate? Do your reporting procedures meet federal standards? NSPS OOOO violations can shutdown operations while you implement corrective measures that should have been standard practice from day one.

Cushing-Specific Compliance Traps

Operating in Cushing creates unique compliance challenges that don't exist in other markets. The concentration of storage facilities, pipeline connections, and regulatory oversight means mistakes that might go unnoticed elsewhere get immediate attention in Cushing.

Permit Violations That Shock Operators

Construction without proper permits remains a recurring compliance failure in the Cushing area. One documented case involved diesel storage tanks and butane offloading equipment constructed without required permits. The penalties were devastating – and completely avoidable.

Every facility modification requires permit review. New equipment, capacity expansions, operational changes, and infrastructure upgrades must receive proper regulatory approval before implementation. "We didn't know we needed a permit" is never an acceptable defense.

Interstate Pipeline Coordination Requirements

Your Cushing facility likely connects to interstate pipeline systems that create additional compliance layers many operators overlook. Pipeline connectivity requirements, transfer documentation, and coordination protocols must meet federal standards that extend beyond basic storage compliance.

Are your pipeline interface procedures properly documented? Do your transfer protocols meet interstate commerce requirements? Pipeline coordination violations can restrict your market access and limit operational flexibility during critical trading periods.

The True Cost of Getting It Wrong

Compliance violations don't just cost money – they destroy business relationships, restrict operational flexibility, and damage reputations that take decades to build. When regulators force operational shutdowns, your customers find alternative storage providers. When violations make headlines, your credibility suffers permanent damage.

Consider the cascading effects of a major compliance failure:

Immediate operational restrictions while you implement corrective measures

Massive financial penalties that strain cash flow and operational budgets

Customer relationship damage when you can't fulfill storage commitments

Insurance complications that increase ongoing operational costs

Regulatory scrutiny that intensifies future inspections and oversight

Your compliance program isn't an expense – it's business survival insurance.

How PSR Transforms Your Compliance Confidence

You don't have to navigate Cushing's complex compliance landscape alone. Premier Safety Resources understands the unique challenges facing oil storage operators in America's pipeline capital. We've helped facilities just like yours avoid the compliance traps that destroy unprepared operators.

Our comprehensive compliance consulting services include:

Complete SPCC plan development and maintenance that evolves with your operations

UST compliance program implementation that exceeds federal requirements

NSPS OOOO compliance strategy tailored to your specific operational profile

Monthly inspection program development that creates bulletproof documentation

Operator training certification that meets all federal and state requirements

Permit coordination assistance that prevents construction violations

Emergency response planning that protects your facility and community

Think of PSR as your compliance insurance policy – we identify potential violations before they become expensive failures.

Your Next Step Toward Compliance Confidence

Don't wait for an inspection to discover your compliance gaps. Every day you operate with unidentified violations, you're rolling the dice with your facility's future. The operators who succeed in Cushing's competitive market are those who proactively address compliance challenges before they become business disasters.

Your facility deserves better than reactive compliance management. You deserve the confidence that comes from knowing your operations exceed regulatory requirements and can withstand the most intensive inspections.

Ready to transform your compliance program from a liability into a competitive advantage? Contact Premier Safety Resources today and discover how our specialized expertise can protect your Cushing Oklahoma oil storage operation from the compliance mistakes that destroy unprepared facilities.

Your success depends on getting compliance right the first time, every time. Let's make sure you do.

Comments