What Is Weld Testing? The Basics Every Small Operator Should Know

- pdoyle57

- Nov 21, 2025

- 5 min read

Your welds could be silently sabotaging your entire operation right now. Without proper testing, you're essentially playing Russian roulette with structural integrity, regulatory compliance, and worker safety. One failed weld doesn't just mean expensive repairs: it could shut down your entire business.

Here's the reality: weld testing isn't optional anymore. It's the difference between running a professional operation and gambling with catastrophic failure. At Premier Safety Resources, we've seen too many small operators learn this lesson the hard way.

What Exactly Is Weld Testing?

Think of weld testing as a comprehensive health check-up for your welded joints. Just like you wouldn't drive a car without knowing if the brakes work, you shouldn't rely on welds without verifying their strength and integrity.

Weld testing is a systematic process that evaluates whether your welded connections can handle the stress, pressure, and conditions they'll face in real-world applications. It's your insurance policy against structural failures, regulatory violations, and safety incidents that could cripple your business.

The process examines everything from surface quality to internal structure, ensuring each weld meets industry standards and can safely perform its intended function. This isn't just about passing inspections: it's about protecting your investment, your workers, and your reputation.

Why Small Operators Can't Afford to Skip This

You might think, "We're a small operation: surely we can get by without all this testing." That's exactly the mindset that leads to devastating failures.

Small operators actually face higher risks than large companies. You don't have the luxury of absorbing massive repair costs or extended downtime. One failed weld in a critical location could mean:

Immediate safety hazards that put your workers at risk

Regulatory violations that result in hefty fines and work stoppages

Costly emergency repairs that drain your operating budget

Insurance complications if failures are traced to inadequate quality control

Reputation damage that affects future contracts and partnerships

Remember, you're competing against larger companies with established quality programs. Professional weld testing levels the playing field by ensuring your work meets the same standards, regardless of your company size.

The Two Pathways to Weld Verification

Weld testing follows two distinct approaches, each serving different purposes in your quality control program.

Non-Destructive Testing: Your First Line of Defense

Non-destructive testing (NDT) examines welds without damaging them. Think of it as an X-ray for your welded joints: you get critical information without affecting the component's ability to perform.

Visual inspection is your most accessible starting point. A trained inspector examines weld surfaces for defects like cracks, porosity, incomplete penetration, and alignment issues. This method requires minimal equipment: typically just proper lighting, magnification tools, and measuring devices.

The beauty of NDT is that your components remain fully functional after inspection. You can verify quality without interrupting production or destroying expensive materials. It's cost-effective for routine quality control and perfect for ongoing maintenance programs.

Destructive Testing: The Ultimate Verification

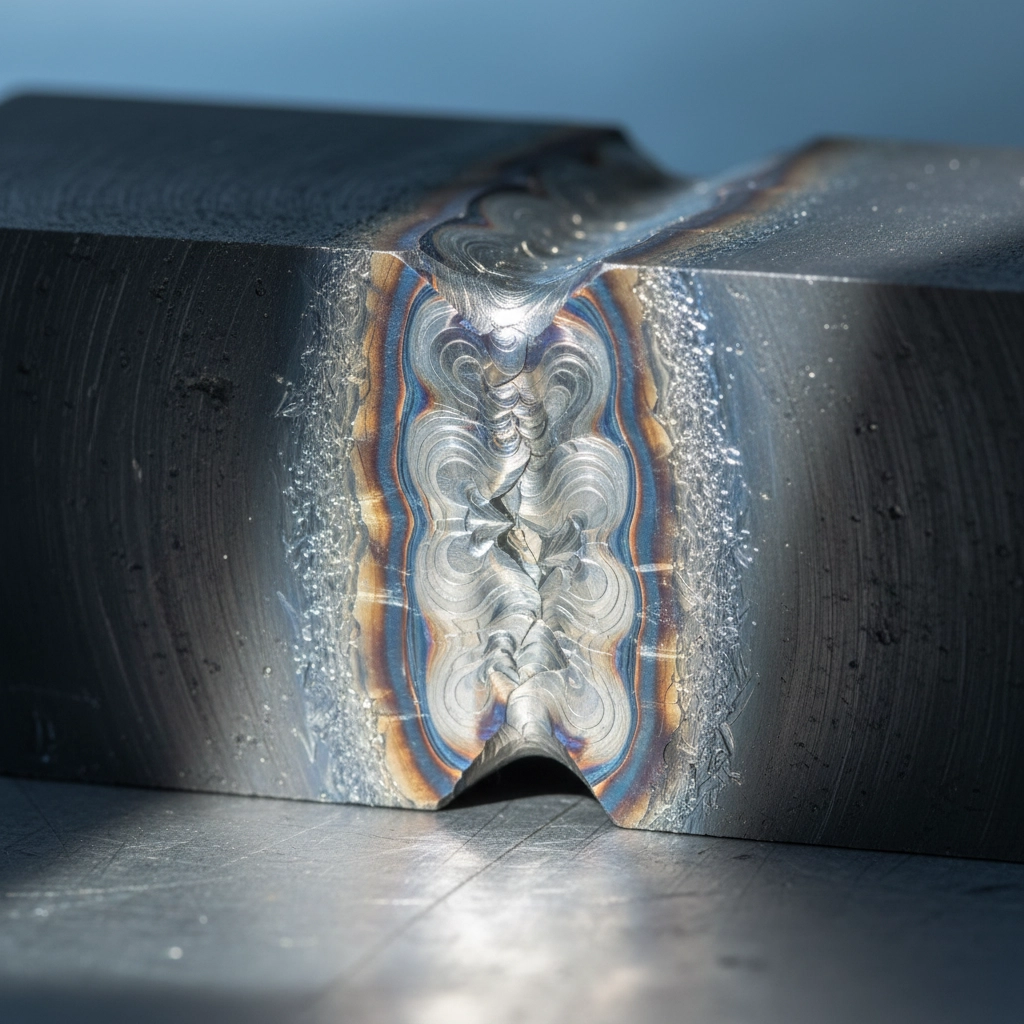

Destructive testing physically challenges your welds to their breaking point. While this means sacrificing test specimens, you gain invaluable data about actual performance under stress.

Tensile strength testing measures exactly how much force your welded joint can withstand before failure. A specialized machine gradually applies pulling force while generating a stress-strain curve that reveals yield stress, ultimate tensile strength, and fracture characteristics.

Bend testing evaluates weld durability under bending forces. Test specimens are placed in bending fixtures and subjected to controlled stress until they crack or break. This reveals weld quality, penetration depth, and fusion with base materials.

Impact testing assesses your weld's ability to absorb sudden shock or loading conditions. This is crucial for applications where unexpected forces could occur.

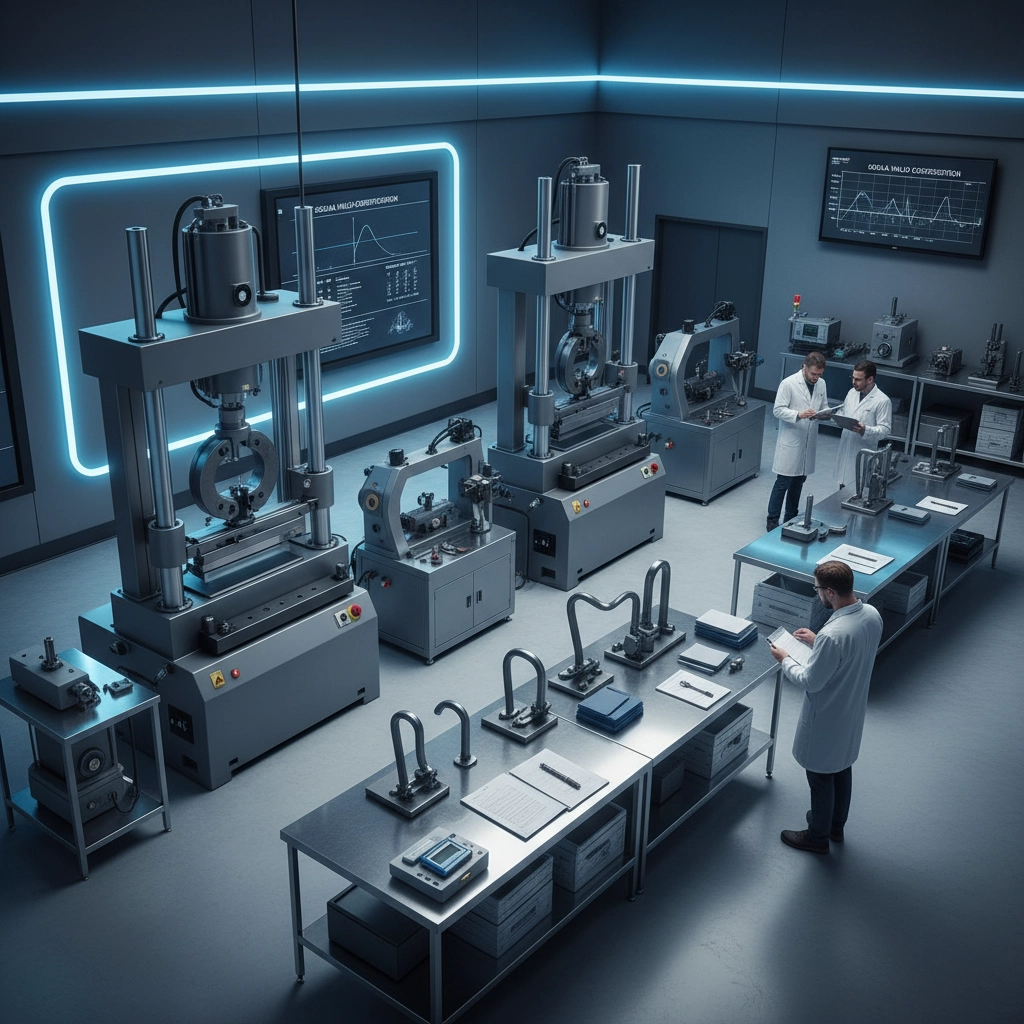

How PSR Transforms Your Weld Testing Program

At Premier Safety Resources, we don't just perform tests: we build comprehensive quality systems that protect your entire operation. Our approach recognizes that small operators need practical, cost-effective solutions that integrate seamlessly with existing workflows.

Our certified inspectors bring decades of real-world experience to your facility. We understand the unique challenges small operators face and design testing programs that maximize value while minimizing disruption.

We start by evaluating your specific applications, materials, and operating conditions. Every testing program we develop is customized to your actual needs: not generic requirements that waste time and money.

Our team provides complete documentation that satisfies regulatory requirements while giving you actionable insights about your welding quality. You get more than just pass/fail results: you receive detailed analysis that helps improve your entire welding program.

Integration with Your Complete Safety Strategy

Weld testing doesn't exist in isolation: it's a critical component of your comprehensive safety and compliance program. This is where PSR's integrated approach delivers exceptional value.

Just like our OSHA compliance consulting services ensure your workplace meets safety standards, weld testing ensures your structural elements meet integrity requirements. Both work together to create a safer, more reliable operation.

Our quality inspection services complement weld testing by evaluating your entire quality management system. When these services work together, you get comprehensive protection that addresses every aspect of operational risk.

Consider how weld testing integrates with other PSR services:

Environmental compliance ensures proper handling of welding materials and waste

Safety training teaches your welders proper techniques that improve weld quality

Respiratory fit testing protects welders from hazardous fumes during the welding process

Your Practical Implementation Roadmap

Getting started with professional weld testing doesn't require massive investments or operational overhauls. Here's your step-by-step approach:

Phase 1: Foundation Building Start with visual inspection training for your team. This builds quality awareness and catches obvious defects before they become expensive problems. PSR provides hands-on training that gives your people confidence in basic quality evaluation.

Phase 2: Critical Application Focus Identify your most critical welded joints: those where failure would have the greatest impact. Begin formal testing on these high-risk applications first. This maximizes your return on investment while building experience with testing procedures.

Phase 3: Program Expansion As your team gains confidence and you see the value, expand testing to additional applications. PSR helps you prioritize based on risk assessment and regulatory requirements.

Phase 4: Continuous Improvement Use testing data to refine your welding procedures and training programs. This creates a feedback loop that continuously improves quality while reducing defects.

The Smart Investment That Pays for Itself

Professional weld testing isn't an expense: it's an investment in operational reliability. Consider the math: the cost of comprehensive testing is a fraction of what you'd spend on emergency repairs, regulatory violations, or safety incidents.

PSR's testing services typically pay for themselves through:

Reduced rework and repairs from catching defects early

Lower insurance premiums from demonstrated quality programs

Avoided regulatory penalties through compliance verification

Improved contract competitiveness from documented quality systems

Ready to Eliminate Weld Uncertainty?

You've built your business on quality work: now it's time to prove it with professional weld testing. Don't let inadequate quality control undermine everything you've worked to achieve.

Premier Safety Resources is ready to design a weld testing program that fits your operation, your budget, and your timeline. Our experts will evaluate your specific needs and create a solution that delivers maximum protection with minimal disruption.

Contact PSR today to schedule your weld testing consultation. Your welds are too important to leave to chance: let's verify their strength together.

Visit psrok.com or call our team to discuss how professional weld testing can strengthen your operation and protect your investment.

Comments